Polyester Plate Lithography

GEORGE ROBERTS developed Polyester Plate Lithography, a new and nontoxic form of lithographic printing while he was Professor of Printmaking at Boise State University. George sadly died in 2001.

The process is more straightforward than conventional lithography as the plate does not require chemical processing in the form of etching with nitric acid etc. Some print shops still use fountain solution and strong acids for printing and processing. The most common problem encountered when printing a polyester plate is “scumming”, when the plate starts picking up ink in areas where it is not wanted.

The clarity of the print is largely determined by the consistency of the ink. An ink that is too soft and viscous (oily) will result in smudging, while a very stiff ink gives a crisp mark, but makes a heavier demand on the durability of the plate. An overly stiff ink may even rip toner marks or other drawing media off the plate during rolling up. As a remedy, use a softer ink and ensure an amount of heat curing before printing. As most of the drawing media used in Polyester Plate Litho are akin to the materials used in ACRYLIC RESIST ETCHING, many of the requirements are similar. Acrylics like heat to aid polymerization, and the new litho process is no exception.

Lindsey Strawn rolling up a pronto plate, Columbia College Chicago

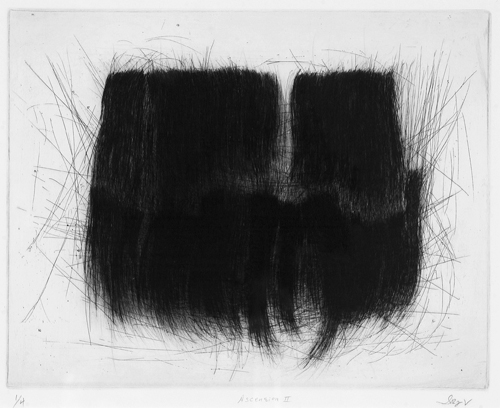

Bernadeta Szopinska. Polyester plate lithograph made using a range of oil and litho crayons, Sharpie, ballpoint pen, and acrylic wash media

Columbia College Chicago, 2008

Laura Shields, polyester plate lithograph